丁基膠涂膠機的操作要注意什么?

時間:2023-07-07 來源:http://www.xyspace.net/ 發布人:昌盛機械

1. 準備工作:將需要涂布的鋁隔條準備好,檢查涂布機的各項參數是否正常。

1. Preparation: prepare the aluminum spacer strip to be coated, and check whether the parameters of the coating machine are normal.

2. 調整設備:根據需要調整涂布機的涂布速度、壓力和溫度等參數,確保涂布質量符合要求。

2. Adjusting equipment: Adjust the coating speed, pressure, and temperature parameters of the coating machine as needed to ensure that the coating quality meets the requirements.

3. 丁基膠涂布機在常溫下呈固體形態,須經過110-150℃得高溫才能融化使用,因丁基膠導熱較慢須加熱20-30分鐘(視氣溫而定)才能完全融化,所以要求每次使用該機之前要加熱膠缸、膠頭(110-150℃下保溫)待膠融化后才能進行工作 。

3. The butyl adhesive coating machine is in a solid form at room temperature and must undergo a high temperature of 110-150 ℃ before melting. Due to the slow thermal conductivity of the butyl adhesive, it needs to be heated for 20-30 minutes (depending on the temperature) to fully melt. Therefore, it is required to heat the rubber cylinder and head (insulated at 110-150 ℃) before each use of the machine before starting work.

4. 監控涂布質量:丁基膠絕對不能出現斷膠,鋁條露白,這是影響中空玻璃壽命的關健。確保涂布的均勻性和厚度符合要求。

4. Monitoring the coating quality: The butyl adhesive must not break or the aluminum strip is exposed, which is a key factor affecting the lifespan of the insulating glass. Ensure that the uniformity and thickness of the coating meet the requirements.

5. 完成涂布:涂布完成后,關閉涂布機的開關,清理涂布機的殘留物和廢料,保持涂布機的清潔。

5. Complete coating: After the coating is completed, turn off the switch of the coating machine, clean the residue and waste of the coating machine, and maintain the cleanliness of the coating machine.

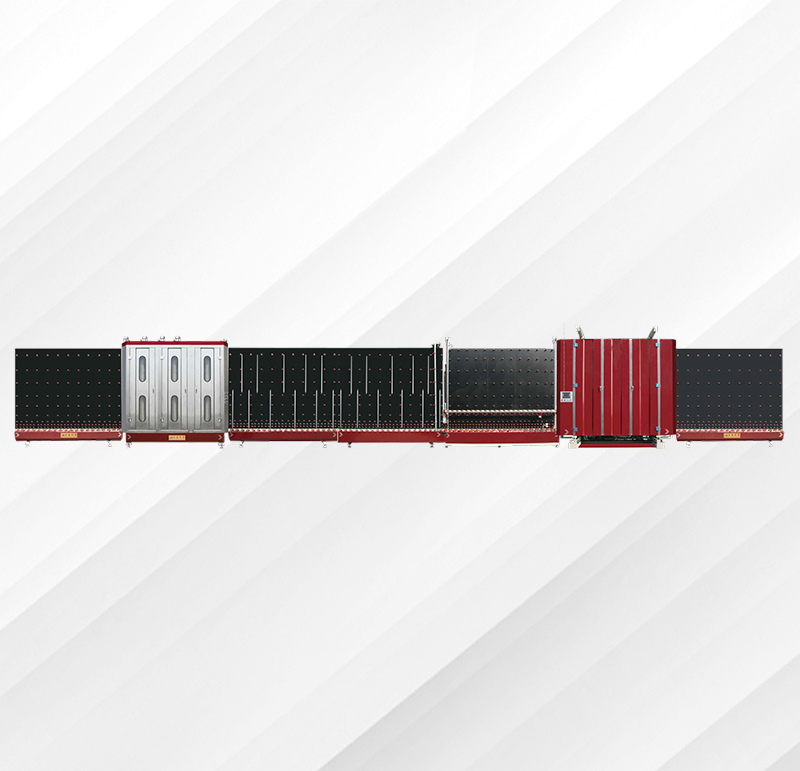

上一篇:中空玻璃全自動封膠線的的使用優勢

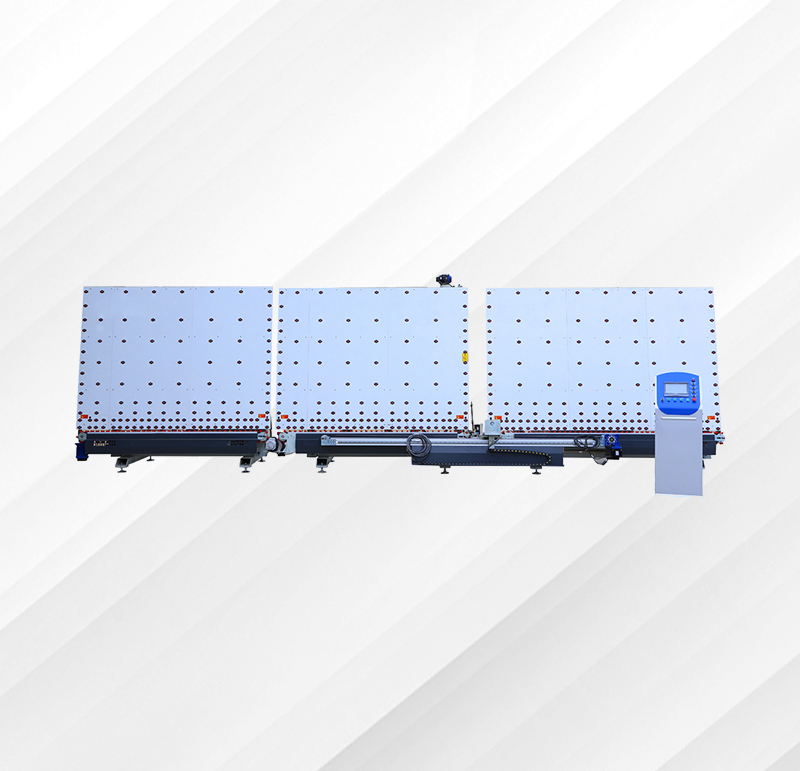

下一篇:全自動鋁條折彎機使用優勢

相關新聞 more+

- 雙組份打膠機:中空玻璃打膠機檢修小竅門必備技能 2025/09/19

- 中空玻璃丁基膠涂布機日常維護全攻略 2025/09/18

- 全自動封膠線憑借高效提升生產效率受到大家的喜愛 2025/09/17

- 玻璃涂布機設備:中空玻璃加工的好幫手 2025/09/16

- 丁基膠涂布機的性能概述 2025/09/13

- 中空玻璃生產線:中空線保養技巧,讓你開工無憂! 2025/09/08

- 雙組份打膠機:雙組分打膠與單組份打膠的簡介及注意事項 2025/08/30

- 雙組份打膠機:中空玻璃自動打膠機的調整與操作 2025/08/30

- 中空玻璃打膠機的調試方法你會了嗎? 2025/08/24

- 中空玻璃生產線:一條中空線至少需要幾個人? 2025/08/23

當前位置:

當前位置:

產品分類Product categories

產品分類Product categories

聯系我們Contact us

聯系我們Contact us