中空玻璃丁基膠涂布機制作流程解析

時間:2025-06-13 來源:http://www.xyspace.net/ 發布人:昌盛機械

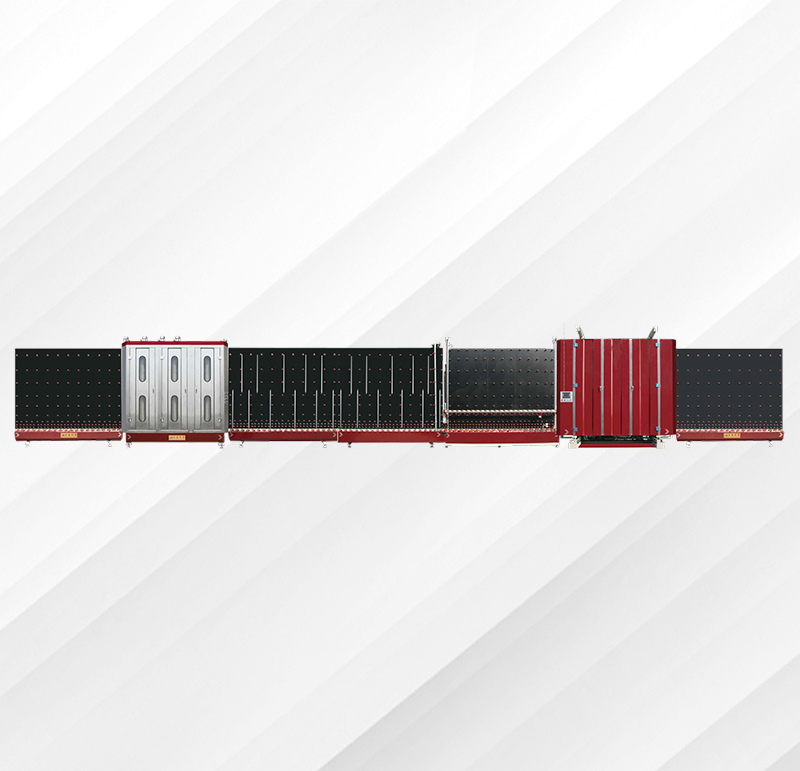

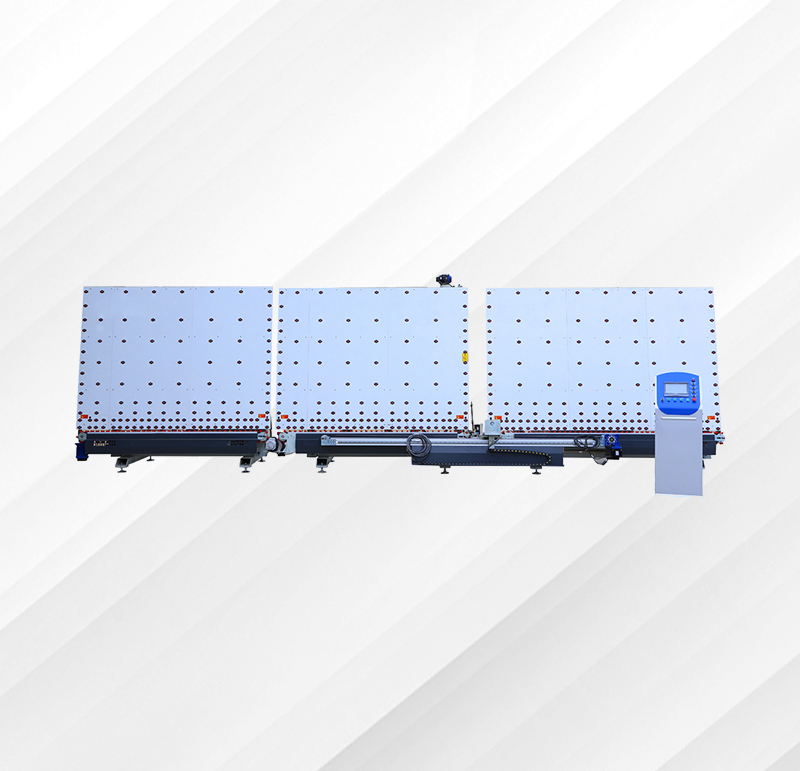

中空玻璃丁基膠涂布機是生產中空玻璃的核心設備之一,其作用是將丁基膠均勻涂布在玻璃鋁隔條上,形成氣密性良好的密封層。設備的制作流程涵蓋設計、加工、裝配、調試四大環節,每個環節的精度控制直接影響最終產品的性能。以下從技術維度詳細解析其制作流程。

The butyl rubber coating machine for insulating glass is one of the core equipment for producing insulating glass. Its function is to evenly coat the butyl rubber on the glass aluminum spacer, forming a sealing layer with good air tightness. The manufacturing process of equipment covers four major stages: design, processing, assembly, and debugging. The precision control of each stage directly affects the performance of the final product. The following provides a detailed analysis of its production process from a technical perspective.

一、設計研發階段

1、 Design and development stage

需求分析與參數確定

Requirement analysis and parameter determination

根據中空玻璃生產企業的需求,明確設備適用范圍。例如,某設備制造商針對幕墻玻璃生產需求,將設備設計為可處理最大尺寸為3.3米×6米的玻璃。

According to the needs of insulating glass production enterprises, clarify the scope of equipment application. For example, a certain equipment manufacturer designed the equipment to handle glass with a maximum size of 3.3 meters by 6 meters for curtain wall glass production needs.

確定關鍵技術參數,包括涂布速度、膠量精度、鋁條厚度適配范圍等。

Determine key technical parameters, including coating speed, adhesive accuracy, aluminum strip thickness adaptation range, etc.

三維建模與結構優化

3D modeling and structural optimization

使用SolidWorks等軟件進行整機三維建模,將設備劃分為供膠系統、涂布系統、傳動系統、控制系統四大模塊。

Use software such as SolidWorks to perform 3D modeling of the entire machine, dividing the equipment into four major modules: adhesive supply system, coating system, transmission system, and control system.

對供膠泵進行流體力學仿真,優化泵體結構以減少膠料殘留;對涂布輥筒進行模態分析,避免高速運轉時產生振動。

Perform fluid dynamics simulation on the glue supply pump, optimize the pump body structure to reduce glue residue; Perform modal analysis on the coating roller to avoid vibration during high-speed operation.

電氣控制系統開發

Development of electrical control system

采用PLC控制器,編寫人機交互界面程序,實現涂布速度、膠量、溫度等參數的數字化設定。

Using a PLC controller, write a human-computer interaction interface program to achieve digital settings of parameters such as coating speed, adhesive amount, and temperature.

集成紅外傳感器與編碼器,構建閉環控制系統,確保涂布位置精度達±0.1毫米。

Integrate infrared sensors and encoders to build a closed-loop control system, ensuring coating position accuracy of ± 0.1 millimeters.

二、零部件加工階段

2、 Parts processing stage

核心部件精密加工

Precision machining of core components

供膠泵體:選用不銹鋼材料,通過五軸加工中心進行銑削、鉆孔,關鍵孔系公差控制在H7級。

Supply pump body: Made of stainless steel material, milled and drilled through a five axis machining center, with key hole tolerances controlled at H7 level.

涂布輥筒:采用超精密車床加工,表面粗糙度達Ra0.4,后續進行硬質氧化處理,提升耐磨性。

Coating roller: processed by ultra precision lathe, with a surface roughness of Ra0.4, followed by hard oxidation treatment to improve wear resistance.

傳動軸:經調質處理后,使用數控磨床進行外圓磨削,圓柱度控制在0.005毫米以內。

Drive shaft: After quenching and tempering treatment, use a CNC grinder for external cylindrical grinding, and control the cylindricity within 0.005 millimeters.

鈑金件制作與表面處理

Sheet metal fabrication and surface treatment

框架采用Q235鋼板,通過激光切割下料,折彎成型后進行焊接。

The frame is made of Q235 steel plate, which is cut by laser cutting, bent into shape, and welded.

防護罩使用SUS304不銹鋼板,表面拉絲處理,提升設備耐腐蝕性。

The protective cover is made of SUS304 stainless steel plate, with a brushed surface treatment to enhance the corrosion resistance of the equipment.

外購件選型與檢驗

Selection and Inspection of Outsourced Parts

伺服電機、減速機、傳感器等關鍵部件選用工業級產品,需通過鹽霧試驗、高低溫循環試驗等可靠性測試。

Industrial grade products are selected for key components such as servo motors, reducers, and sensors, and reliability tests such as salt spray tests and high and low temperature cycling tests are required.

三、整機裝配階段

3、 Whole machine assembly stage

預裝配與尺寸校驗

Pre assembly and dimension verification

在裝配平臺上進行部件預組裝,使用激光跟蹤儀檢測關鍵安裝面的平面度與垂直度。

Pre assemble components on the assembly platform and use a laser tracker to detect the flatness and perpendicularity of key installation surfaces.

對供膠管路進行壓力測試,確保在2倍工作壓力下無泄漏。

Perform pressure testing on the adhesive supply pipeline to ensure no leakage at twice the working pressure.

模塊化裝配工藝

Modular assembly process

傳動系統裝配:采用熱裝工藝將齒輪與軸配合,過盈量控制在0.02-0.04毫米。

Transmission system assembly: The gear is matched with the shaft using hot assembly technology, and the interference fit is controlled at 0.02-0.04 millimeters.

涂布系統裝配:使用激光對中儀調整涂布輥筒與鋁條輸送帶的平行度,誤差≤0.05毫米。

Coating system assembly: Use a laser alignment device to adjust the parallelism between the coating roller and the aluminum strip conveyor belt, with an error of ≤ 0.05 millimeters.

電氣接線與氣路布置

Electrical wiring and gas circuit layout

電纜采用高柔性拖鏈電纜,走線槽內預留20%余量,避免運行中產生拉扯。

The cable adopts a highly flexible drag chain cable, with a 20% margin reserved in the cable tray to avoid pulling during operation.

氣動元件安裝防震接頭,氣路壓力通過精密減壓閥穩定在0.6MPa±0.02。

Pneumatic components are installed with shockproof joints, and the air pressure is stabilized at 0.6MPa ± 0.02 through a precision pressure reducing valve.

四、調試與驗證階段

4、 Debugging and Verification Phase

空載調試

No load debugging

手動模式檢查各軸運動范圍,驗證限位開關有效性。

Check the range of motion of each axis in manual mode and verify the effectiveness of the limit switch.

自動模式運行72小時,記錄電機溫升、傳動噪音等數據,確保設備穩定性。

Run in automatic mode for 72 hours, record data such as motor temperature rise and transmission noise to ensure equipment stability.

涂布工藝驗證

Coating process validation

使用標準鋁條進行試涂布,檢測膠層厚度均勻性,要求CV值≤3%。

Use standard aluminum strips for trial coating, check the uniformity of the adhesive layer thickness, and require a CV value of ≤ 3%.

進行耐候性測試,將涂布樣品置于85℃/85%RH環境中1000小時,觀察膠層剝離強度變化。

Conduct weather resistance testing by placing the coated sample in an environment of 85 ℃/85% RH for 1000 hours and observing changes in the peel strength of the adhesive layer.

客戶現場驗收

Customer on-site acceptance

模擬實際生產節拍,連續運行3個班次,統計設備綜合效率。

Simulate the actual production pace, run continuously for 3 shifts, and calculate the comprehensive efficiency of the equipment.

培訓操作人員掌握設備維護、故障診斷、參數優化等技能。

Train operators to master skills such as equipment maintenance, fault diagnosis, and parameter optimization.

五、質量管控體系

5、 Quality control system

過程檢驗

Process inspection

關鍵工序設置質量控制點,如供膠泵裝配后需進行流量標定。

Set quality control points for key processes, such as flow calibration after the assembly of the glue pump.

使用三坐標測量機對機架進行全尺寸檢測,出具檢測報告。

Use a coordinate measuring machine to conduct full-scale inspection of the rack and issue an inspection report.

成品檢測

Finished product testing

依據標準進行安全檢測,包括急停響應時間、防護罩強度等。

Conduct safety inspections according to standards, including emergency stop response time, protective cover strength, etc.

進行涂布質量抽檢,使用X射線熒光光譜儀檢測膠層元素分布。

Conduct coating quality sampling and use X-ray fluorescence spectrometer to detect the distribution of adhesive layer elements.

中空玻璃丁基膠涂布機的制作流程是機械、電氣、材料、控制等多學科技術的集成應用。通過模塊化設計、精密加工、嚴格裝配、多維調試,設備可實現高效、穩定的丁基膠涂布作業。隨著智能制造技術的發展,未來的涂布機將集成機器視覺與AI算法,實現膠型缺陷的在線識別與自動修正,進一步推動中空玻璃生產線的智能化升級。

The production process of the butyl rubber coating machine for insulating glass involves the integrated application of multidisciplinary technologies such as mechanical, electrical, material, and control. Through modular design, precision machining, strict assembly, and multidimensional debugging, the equipment can achieve efficient and stable butyl rubber coating operations. With the development of intelligent manufacturing technology, future coating machines will integrate machine vision and AI algorithms to achieve online recognition and automatic correction of adhesive defects, further promoting the intelligent upgrading of insulated glass production lines.

本文由中空玻璃丁基膠涂布機友情奉獻.更多有關的知識請點擊:http://www.xyspace.net我們將會對您提出的疑問進行詳細的解答,歡迎您登錄網站留言.

This article is a friendly contribution from glass coating machine equipment For more information, please click: http://www.xyspace.net We will provide detailed answers to your questions. You are welcome to log in to our website and leave a message

- 雙組份打膠機:中空玻璃打膠機檢修小竅門必備技能 2025/09/19

- 中空玻璃丁基膠涂布機日常維護全攻略 2025/09/18

- 全自動封膠線憑借高效提升生產效率受到大家的喜愛 2025/09/17

- 玻璃涂布機設備:中空玻璃加工的好幫手 2025/09/16

- 丁基膠涂布機的性能概述 2025/09/13

- 中空玻璃生產線:中空線保養技巧,讓你開工無憂! 2025/09/08

- 雙組份打膠機:雙組分打膠與單組份打膠的簡介及注意事項 2025/08/30

- 雙組份打膠機:中空玻璃自動打膠機的調整與操作 2025/08/30

- 中空玻璃打膠機的調試方法你會了嗎? 2025/08/24

- 中空玻璃生產線:一條中空線至少需要幾個人? 2025/08/23

當前位置:

當前位置:

產品分類Product categories

產品分類Product categories

聯系我們Contact us

聯系我們Contact us